Search

Search

Search

Search

Explore the products below, classified into their functions or testing methods.

Talk to an Expert

Used in the determination of the Aniline Point of petroleum products and hydrocarbon solvents.

Measures the Stuck Tendency Coefficient with the Timed Filtrate Test.

Electrical stability test used to monitor a fluid’s emulsion stability and oil-wetting capability.

Shows the amount of reactive clays (bentonite and/or drill solids) present in drilling fluid

Simple, accurate and inexpensive sieve analysis apparatus for determining the sand content of drilling muds

Field measurement of drilling fluid or filtrate pH and adjustments to the pH are fundamental to drilling fluid control.

Simple, accurate, and reproducible test method for particle size analysis by wet sieving, as specified in API Specification 13A.

Fann manufactures a variety of instruments to test the viscosity of a drilling fluid or mud.

Drilling fluid is subjected to a period of shear and allowed to more fully develop its rheological and filtration properties in an aging cell.

Drilling fluids are mixed or sheared for the appropriate time to achieve a homogenous mixture and are then set aside to "age"

Roller ovens provide an excellent method of aging drilling fluid samples.

High Temperature Roller Ovens provide an excellent method of aging drilling fluid samples. 600F

Drilling fluid formulations are commonly mixed with various shearing devices with either fixed or variable speeds.

High Shear Mixer (Dispersator) utilizes a patented mixing head that pumps material into the hollow mixing chamber and outward through the chamber openings.

For use with field test kits. Mixer speed is 15,000 rpm. It features a spring clip and mud shield.

Two speed mixer, standard impeller blade for mixing either water-based or oil-based drilling fluids.

Five-Spindle Multi-Mixer® Model 9B mixer is recommended for use in general purpose mixing of drilling fluids.

Calcimeters can determine quickly and with a high degree of accuracy if the scale buildup is composed of calcium carbonate.

Placing corrosion test rings in the drill string is used to evaluate the corrosiveness of drilling fluids on the drill string and steel equipment

Designed for testing fluids at temperatures up to 500°F (260°C) and pressures to 2,500 psig (17,237 kPa).

Fann corrosion coupons are made of Cold Drawn seamless mechanical tubing from type 4130 machine-finish steel.

It is a colorimetric method that uses the same Hydrogen Sulfide Test paper discs as the Garrett Gas Train and can detect as little as 0.3 ppm H2S.

Test steel armor wire (and other steel objects) for the presence of iron sulfide, which can be indicative of exposure to hydrogen sulfide.

Density or mud weight is fluid weight per unit of volume. Monitoring density is to control formation pressures and minimize loss of returns.

The Fann Porta Lab family of products has been used by drilling fluid engineers around the world for over forty years.

Contains all equipment and reagents required to test fluids for chloride content according to API Recommended Practice 13B-1

For use with field test kits. Mixer speed is 15,000 rpm. It features a spring clip and mud shield.

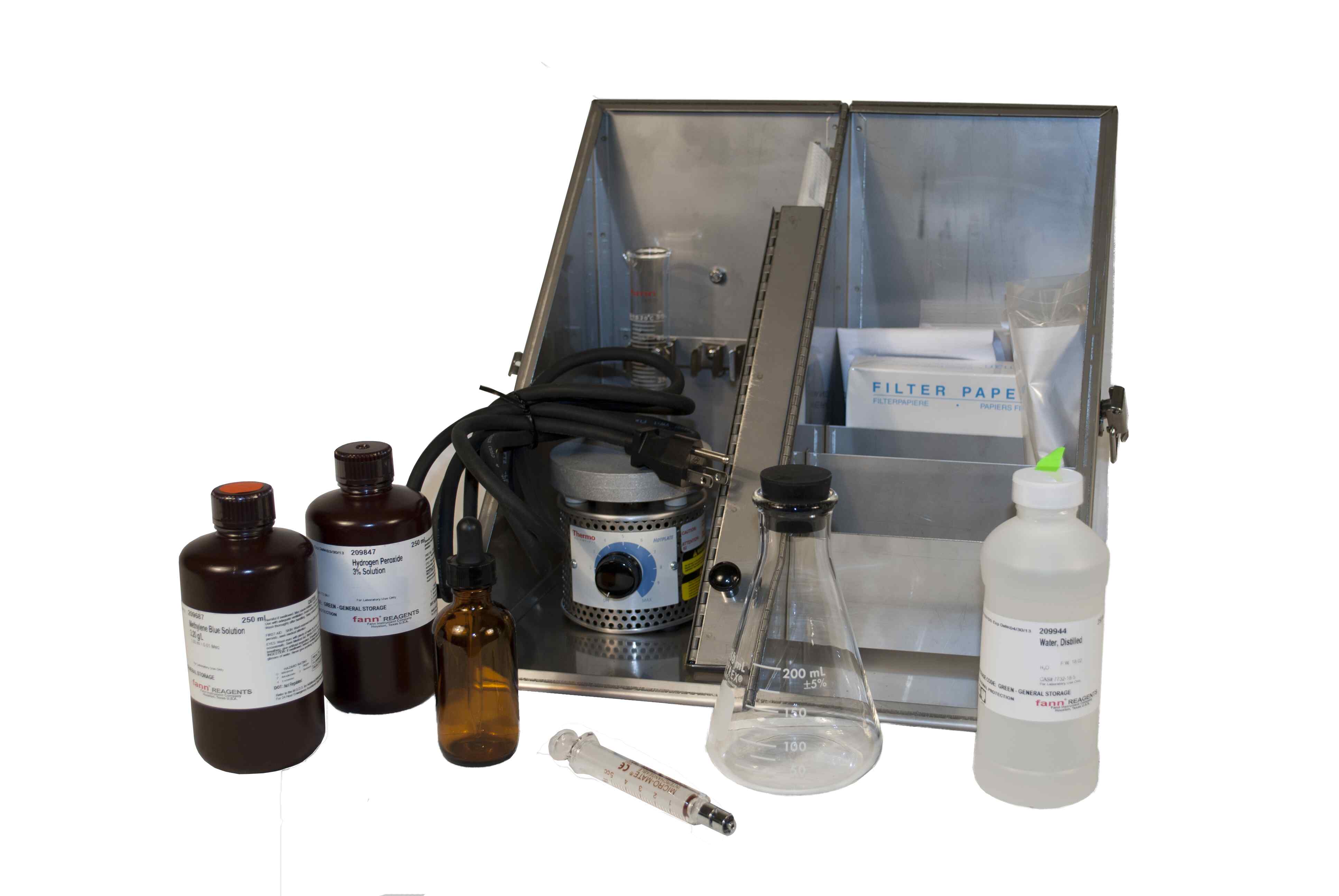

Compliment to the Basic Mud Testing Kit by providing all necessary drilling fluid testing equipment required for field testing.

Mud systems with Partially Hydrolyzed Polyacrylamide (PHPA) Polymer are used and have proven effective. Versatile for inhibiting troublesome shale formations

Contains the basic mud testing equipment required for routine mud checks by rig personnel

MicroTPI is a necessity for monitoring turbidity. Shock-resistant carrying case holds everything necessary for field operation.

Measurement of the filtration behavior and wall-cake-building characteristics of a drilling fluid is essential for design.

Effective means of determining the filtration properties of drilling muds and cement slurries.

Filter Press unit can be pressurized to 1800 psig on the cell and 750 psig on the back pressure receiver. Maximum operating temperature is 500°F

Safe and efficient high-temperature; high-pressure fluid loss testing that meets API specifications. The digital system is accurate and controllable.

Designed to reduce the chance of accidental opening of the Filter Press cell while still under pressure.

Hydraulic weight creating 100psi pressure and determining the filtration properties of drilling muds and cement slurries.

Calendared, hardened, qualitative low-ash filter paper used to filter fine precipitates with the following qualities.

Simulation and measurement of downhole static filtration. Useful in predicting permeable filter cake to seal off depleted/under pressure intervals.

Automated Permeability Plugging Apparatus (APPA)

5,000 psig rated PPA is ideal for predicting how a drilling fluid can form a permeable filter cake to seal off depleted/under pressure intervals.

An alternative back pressure receiver for the Fann® Permeability Plugging Apparatus (PPA) and Automated Plugging Apparatus (APPA).

Resistivity meters measure the resistivity of fluids, slurries or semi-solids.

Knowledge of water, oil and solids content is fundamental to proper control of mud properties such as: oil/water ratio, rheology, density, filtration.

Space saving design, enhanced safety features enabling accurate retorting to any of the three recommended API sample volumes.

Use to determine the quantity of liquids and solids in a drilling fluid

Use to determine the quantity of liquids and solids in a drilling fluid

A 5-cell, 50ml oil and water retort which allows more accurate, faster, consistent, and convenient gathering of oil water ratio.

Tests used to determine if a specific shale is likely to cause problems include the capillary suction time (CST) test and the linear-swell meter (LSM)