Search

Search

Search

Search

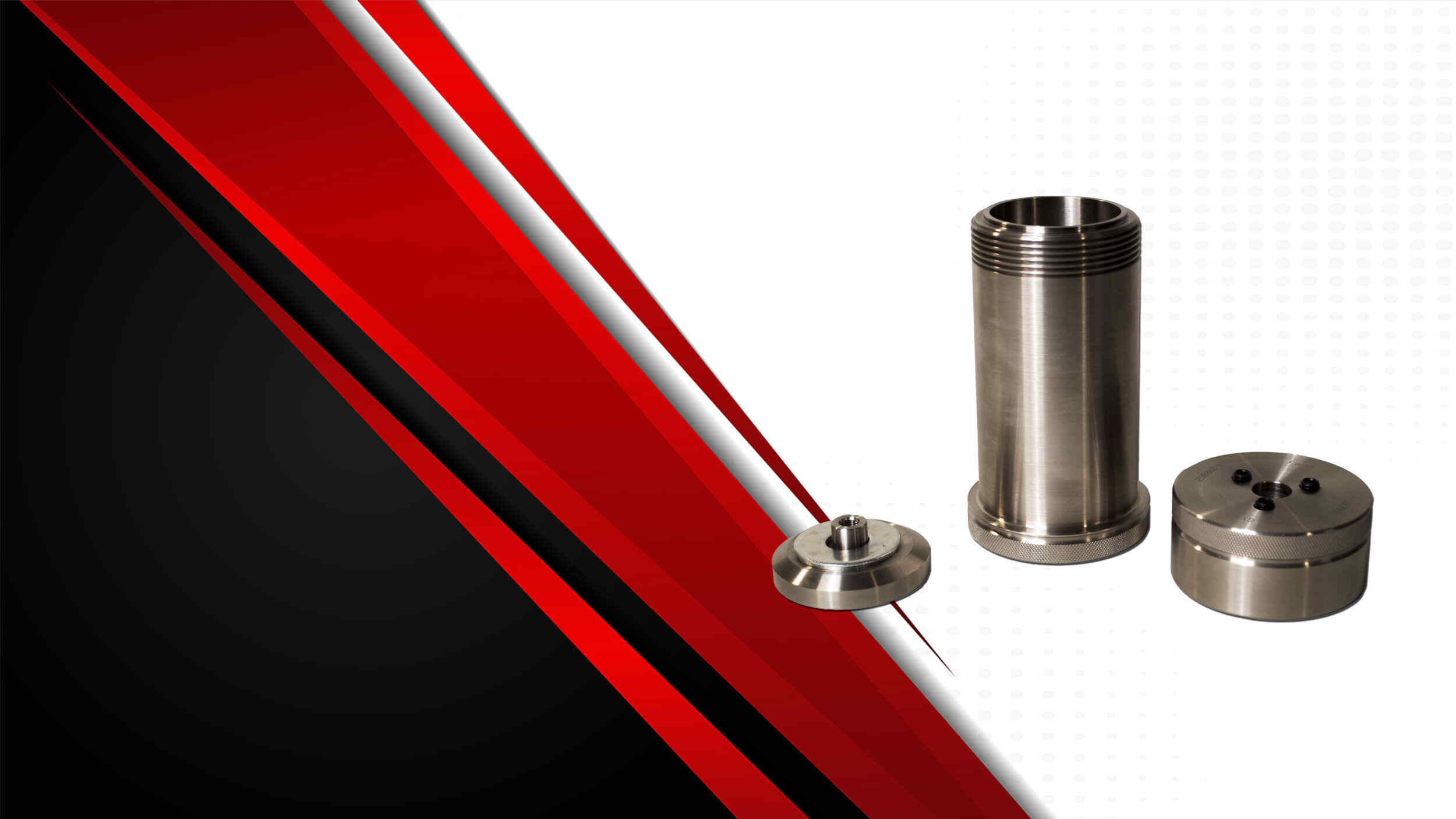

Fann aging cells are designed to be used with Fann Instrument Company products, such as roller ovens, in the aging and testing of drilling fluids or muds.

Contact UsAlso known as Mud Aging cells. Most drilling fluid formulations contain a base liquid and additives which must be dissolved or mechanically dispersed into the liquid to form a homogenous fluid.

Drilling fluids are mixed or sheared for the appropriate time to achieve a homogenous mixture and are then set aside to age. Aging is done under conditions which vary from static to dynamic and from ambient to highly elevated temperatures.

Ordering Information and Specifications

Part No. 102111608— 600DegF High Temperature Aging Cell, 550 ml

| Part No. | Material | Volume | Maximum Working Pressure |

Maximum Temperature |

||

| ml | psig | kPa | °F | °C | ||

| 210285 | 303 Stainless Steel | 500 | 2500 | 17237 | 500 | 260 |

| 210286 | 316 Stainless Steel | 500 | 2500 | 17237 | 500 | 260 |

| 2102882 | 303 Stainless Steel | 260 | 2500 | 17237 | 3501 | 177 |

| 210289 | 303 Stainless Steel | 260 | 2500 | 17237 | 3501 | 177 |

| 2102902 | 303 Stainless Steel | 500 | 2500 | 17237 | 500 | 260 |

| 210291 | 316 Stainless Steel | 260 | 2500 | 17237 | 3501 | 177 |

| 2102922 | 316 Stainless Steel | 260 | 2500 | 17237 | 3501 | 177 |

| 2102943 | 303 Stainless Steel | 500 | 2500 | 17237 | 500 | 260 |

| 2103162 | 316 Stainless Steel | 500 | 2500 | 17237 | 500 | 260 |

1Cells are rated at 350°F (177°C) since allowable sample size becomes less than 200 ml at higher temperatures.

2Cells cannot be pressurized.

3Corrosion coupon holder and gas injection tube are mounted to inner cap