Search

Search

Search

Search

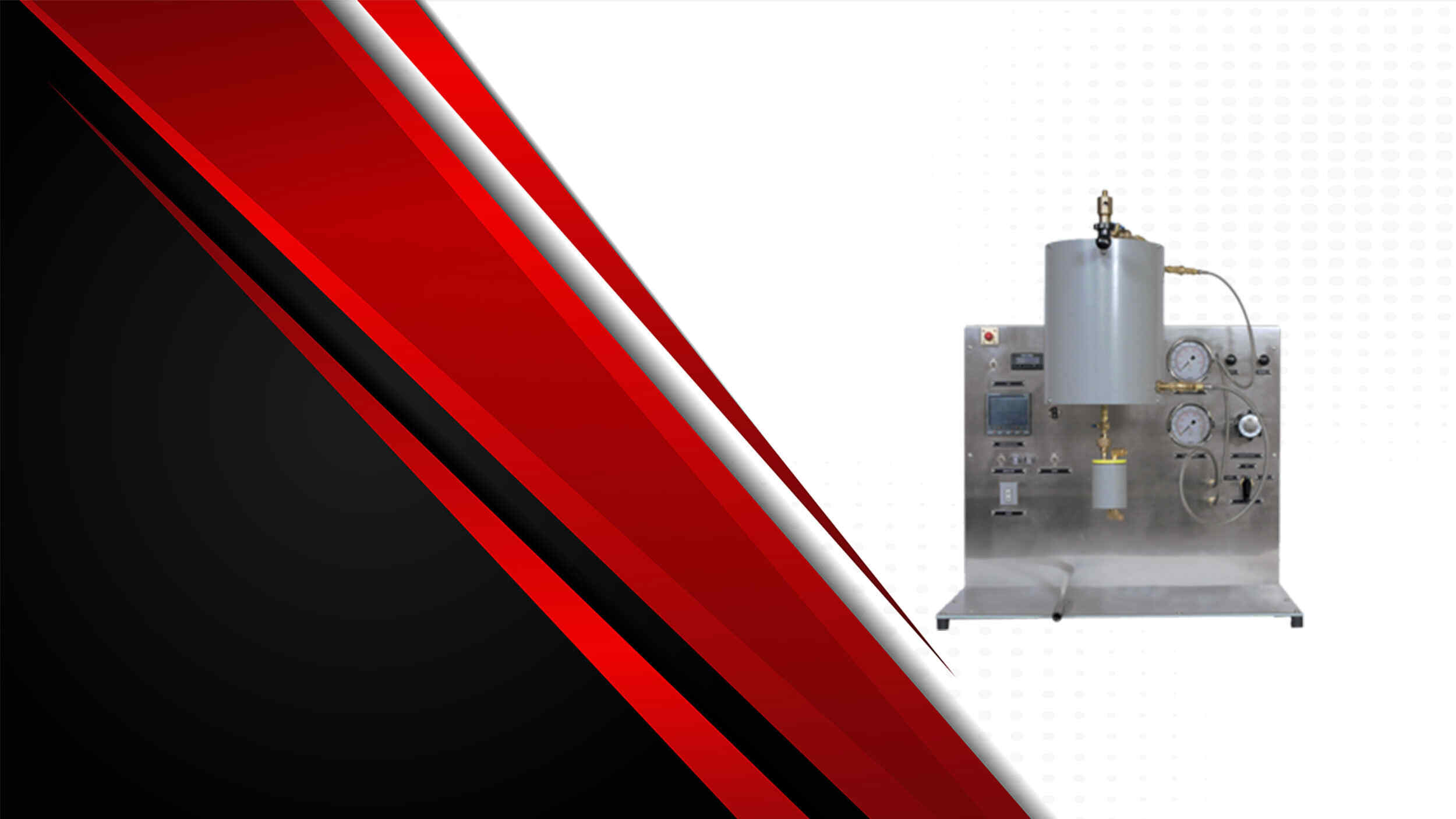

The Stirring Fluid Loss Test Assembly provides a reliable means of determining the fluid loss characteristics of an Oil Well Cement.

Contact UsThis apparatus simulates down-hole conditions where fluid loss can occur. When cement slurry is circulated past a permeable zone, pressure behind the slurry can force fluid out of the slurry and into the zone. Circulation is simulated by a stirring apparatus and circulation temperature is simulated by a heating jacket. The pressure differential between annular and formation pressure is simulated by pressurized nitrogen. A screen (or porous core) and a filtration chamber simulate the permeable zone.

Slurry preconditioning and testing are performed in the same cell, eliminating the need to cool, or transfer hot test slurry, possibly changing the properties of the test slurry.

While the slurry is being heated, the stirring paddle maintains slurry uniformity. Nitrogen pressure is applied to the test fluid. Filtrate is forced through a filter medium. Fluid loss is measured as filtrate volume per unit of time.

Stirring Fluid Loss Cells are fitted with a 325 mesh screen [3.5 in² (22.6 cm²) filtration area] backed by a 60 mesh screen. The 60 mesh screen provides a flow path for the cement filtrate as outlined in API Recommended Practice 10B. Cells are provided with openings on both ends with caps (double ended) for ease of maintenance.

Part No. 210194 - Stirring Fluid Loss Assembly, 230 Volt, 50 Hz

Note: Images of products are provided for illustrative purposes only. The actual product you receive may vary

from the image displayed on this web site.